After considerable delay the wooden hive (National configiration) finally arrived from Donegal Bees:

First, the contents were unpacked. Was surprised to find that there were no instructions for assembly of the flatpack items. Not a good start! Tried the supplier website but could not find instructions there either. Luckily I was able to find an excellent step by step instruction video on the Thorne site so work could begin.

The hive base contained further component items which were easily extracted. Work could commence on the assembly of the brood box.

The inner walls of the brood box were arranged on the workbench and the runner rails were positioned in place on the edges leaving equal edge gaps at both ends.

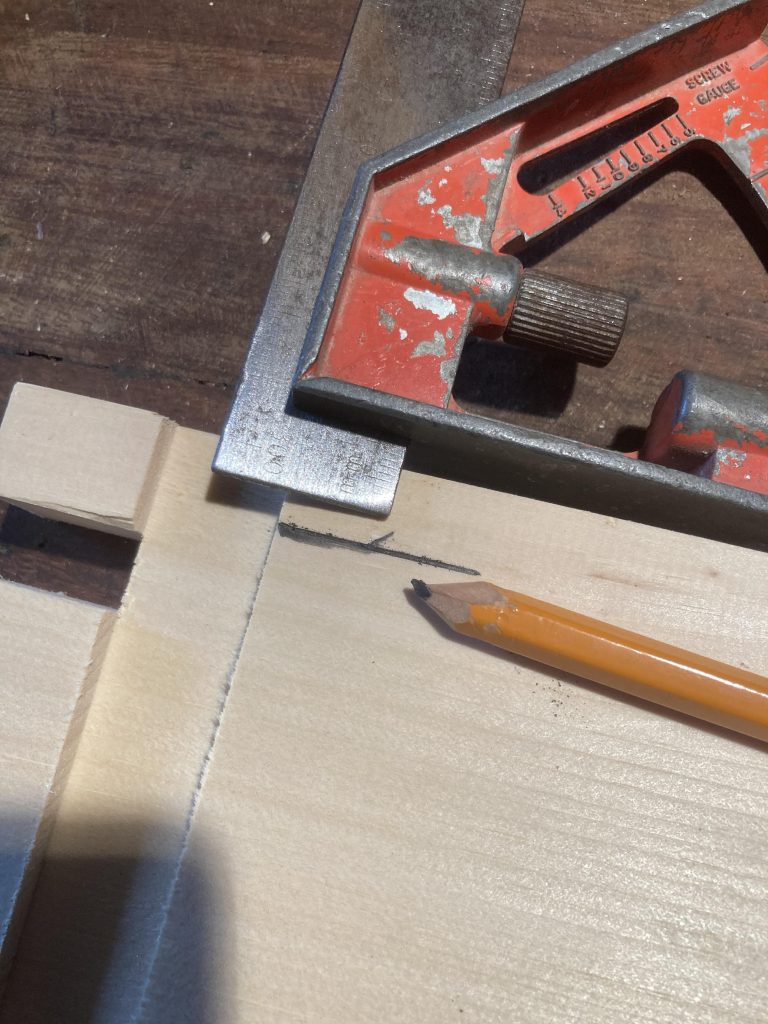

Next pencil lines/marks were placed on the outer walls 11 mm from the top edge. These marks will act as alignment marks between the runners on the inner walls and the outer walls so as to position the frames correctly in the box leaving the appropriate ‘beespace’ at the bottom. Therefore, this is a critical step and should be done with as much accuracy as possible.

The hive is now ready for inspection and certification by an experienced beekeeper. If it passes its inspection we can proceed to painting and decorating – we need a colourful distinguishing target painted on the front of the hive so the bees can recognise their hive from all the others in the Apiary. Suggestions welcome.